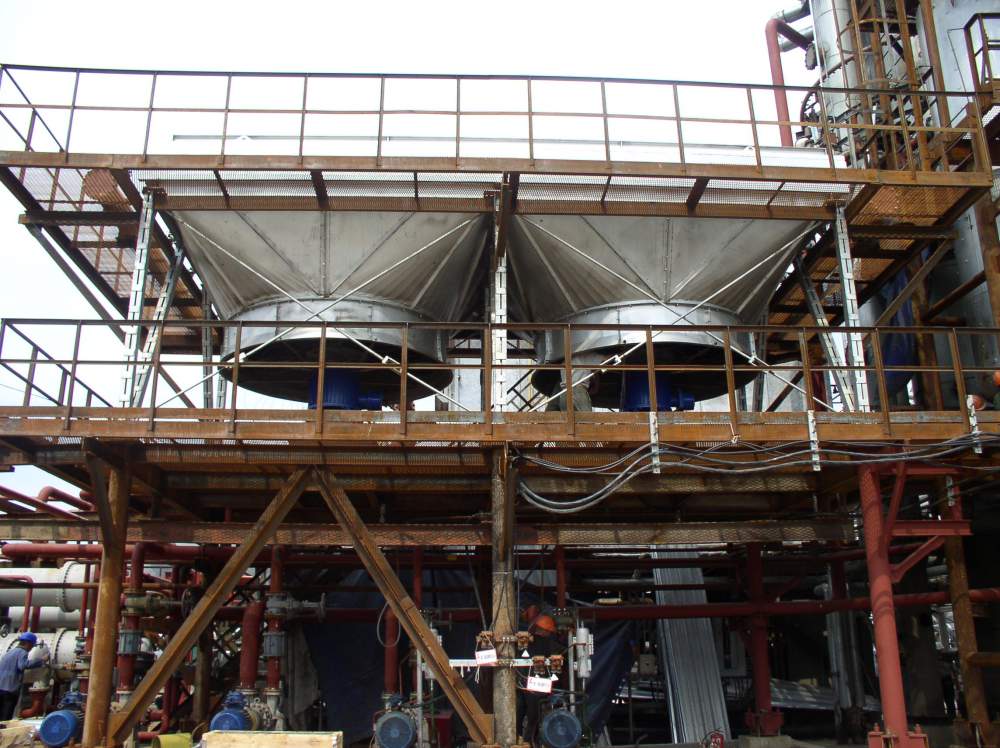

Air cooling unit with ribbed tubes is one of the types of heat exchange equipment at refining plants. Taking into consideration structural particularities of air cooling units, the repair of heat exchange tubes is an extremely complicated task and in certain cases is impossible.

Air cooling unit with ribbed tubes is one of the types of heat exchange equipment at refining plants. Taking into consideration structural particularities of air cooling units, the repair of heat exchange tubes is an extremely complicated task and in certain cases is impossible.

In this situation, installation of metal tube shields inside damaged tubes with the use of hydraulic expansion may become the only possible alternative of expensive replacement of a tube bank in air cooling units.

A huge advantage of thin-wall tube shields is a possibility of their local installation in the most damageable tube parts (for instance, at the inlets), thus protecting these areas for a longer term from erosive influence of aggressive high-temperature environments.

Using extra strong and corrosion-proof alloys for manufacturing tube shields that significantly increase the original source material by properties, it is possible to achieve a multiple increase in performance of a tube bank in air cooling units. Especially it is important for air cooling units located at heights or hard- to-reach places, for the costs for replacement of their tube banks taking into account concomitant works is extremely high.

The service of installing tube shields in new air cooling units designed for work in complicated conditions gains all the more popularity in the world. Due to the use of specially selected materials, it is possible to significantly prolong the service life of these air cooling units with the relatively low cost of such service.