One of the most widespread problems in condensing steam units of turbogenerators is failures in heat exchange tubes. The longer a condensing unit functions, the higher the number and frequency of tube failures are. It leads to a decrease in the efficiency of condensation of waste steam as well as in the performance factor of a whole unit. A number of units related to elimination of leakage is in a continuous increase, lowering the operational efficiency of the unit and increasing the consumption of condensate water for system filling. Sooner or later, the operational service faces a problem of repairing or replacing the condenser.

One of the most widespread problems in condensing steam units of turbogenerators is failures in heat exchange tubes. The longer a condensing unit functions, the higher the number and frequency of tube failures are. It leads to a decrease in the efficiency of condensation of waste steam as well as in the performance factor of a whole unit. A number of units related to elimination of leakage is in a continuous increase, lowering the operational efficiency of the unit and increasing the consumption of condensate water for system filling. Sooner or later, the operational service faces a problem of repairing or replacing the condenser.

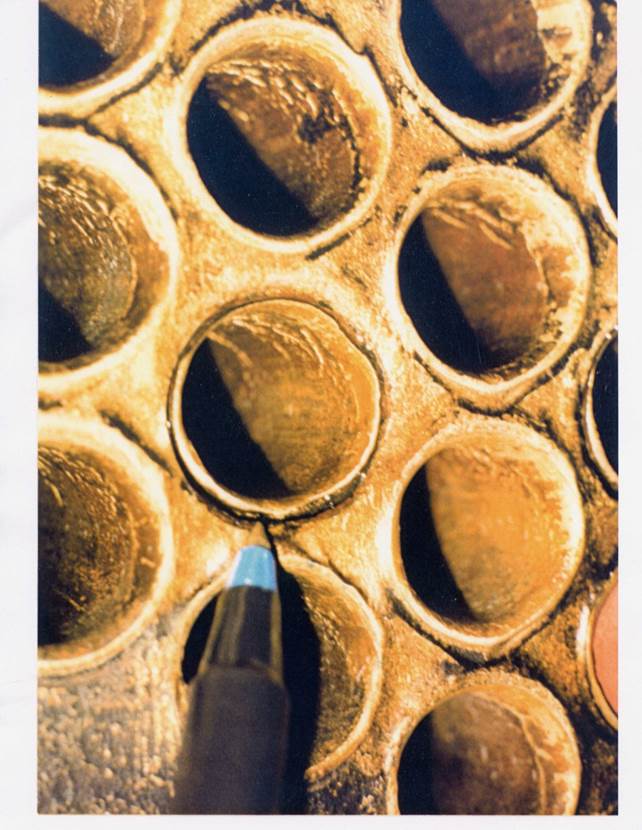

In this situation, a possibility of restoring previously blanked-off tubes and protecting functioning tubes with the aid of metal shields can be viewed as an alternative. As a rule, the cost of restoring heat exchange tubes using tube shields is 5-10 times lower than replacing an entire tube bank. Moreover, in “old” units such work for replacing the tube bank leads to a significant number of concomitant and expensive work.

Срок выполнения работ по установке трубных вставок несравнимо меньше требуемого времени на замену трубного пакета.

Work execution time for installing tube shields is comparably lower than the required time for replacing a tube bank.

For determining the technical condition of condensers and heaters, NORDWEG JSC offers to perform a profound inspection of a condensing unit. Such typical inspection includes:

For determining the technical condition of condensers and heaters, NORDWEG JSC offers to perform a profound inspection of a condensing unit. Such typical inspection includes:

According to the results of a conducted inspection, a technical report with the results and recommendations is drawn up.